Space Shuttle Launch Complex 39-B Construction Photos

Page 43

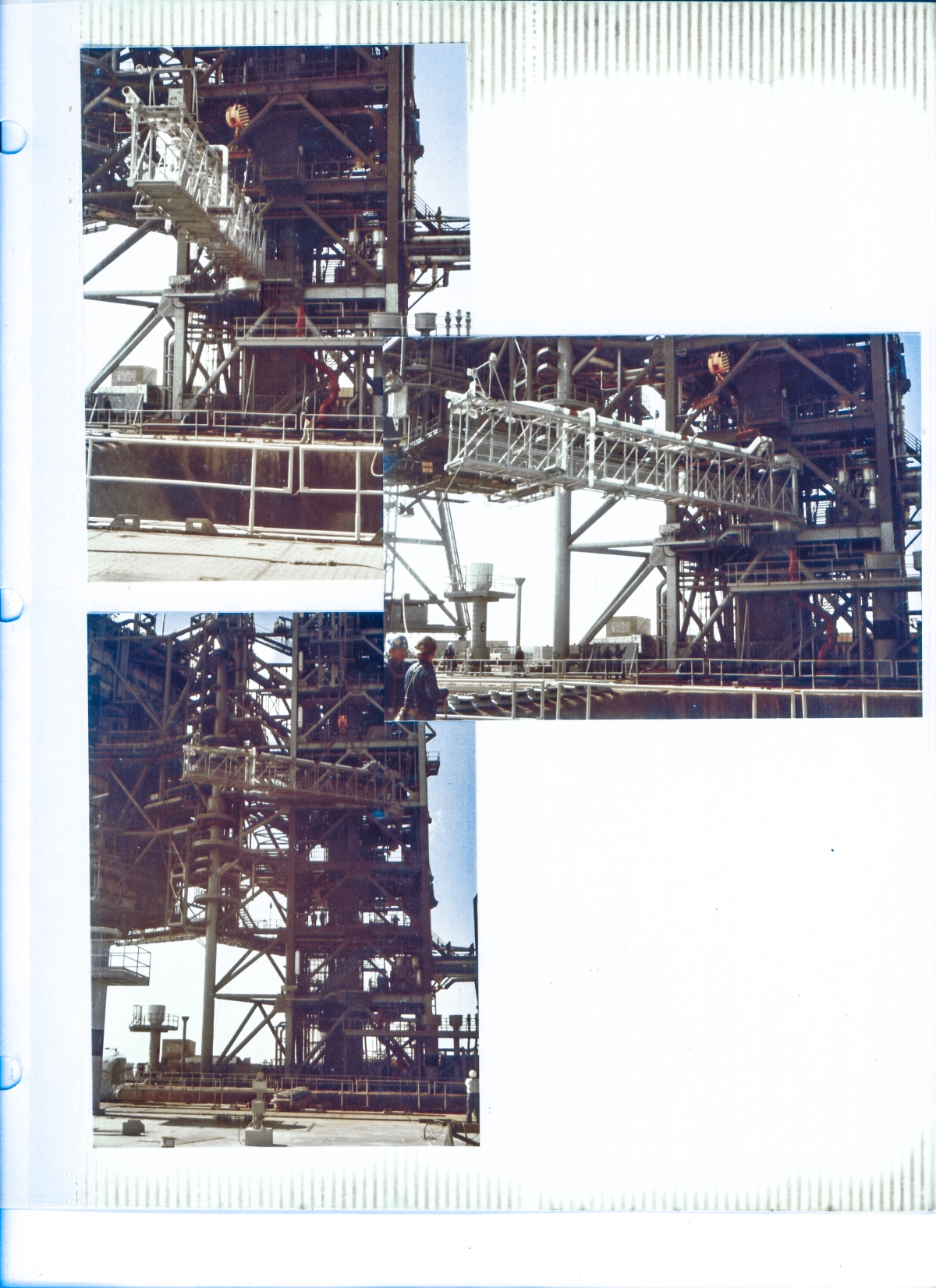

GOX Arm Lift 2 (Original Scan)

As the lift continues, the ironworkers continue to rotate the Gox Arm around to its final installation orientation.

Top: (Full-size with masking)

I found the overlapping image from the original scan above to be unduly distracting, and for that reason, I masked it out with solid black in an attempt to try to keep things a little less confusing, visually.

As the lift continues, our crew of ironworkers continue to rotate the arm around toward its final orientation by working the tag lines as it continues its upward journey to the top of the FSS.

The arm is now more or less in the east-west orientation it would be in, if there was an orbiter on the pad and the vent hood (which has yet to be installed on the end of the truss) was engaged with the External Tank, but its location right-to-left (north-south) with respect to the FSS behind it is incorrect. The strongback which supports it is offset almost all the way to the north side of the FSS, and that's where the truss needs to be bolted up, and for now, that cannot happen with the truss located where it is in this frame, aligned with the centerline of the FSS. But look close, and you will see the lower hinge box is facing almost due south, and this too is incorrect for a final installation. Once the arm has finished rotating all the way around to its final install orientation, the truss will be aligned more or less north-south, placing the hinge boxes far enough to the right to permit the crane operator to pull his load back in toward the FSS and allow the bolt holes in the hinge boxes and in the strongback which will support them, to be mated, and then allow bolts to be inserted through them and torqued down.

And in case you're wondering, lifting the truss with the Hammerhead Crane, involved locating it in a pretty narrow area between the FSS and the Flame Trench, right at the base of the FSS, or otherwise the Hammerhead Crane would never have been able to reach it in the first place, and the logistics of getting the truss up on the pad and setting it down in its to-be-lifted position were such that turning the arm around to get the hinge boxes on the north end, instead of the south end as seen in these images, involved significantly more time and effort than wound up being expended on simply pulling on the tag lines as it went up, and spinning it around to its final orientation that way. Yet another example of Ironworker Cunning. They tell you to "Work smart, not hard," but in truth, the best results are gotten when you "Work smart and hard."

Center: (Reduced)

The rotation of the arm continues, and as I pan the camera around to the left, and continue to step back to keep everything of interest in the frame, you can see that there are a lot of people involved, working this lift.

The people in view also serve to give a proper sense of scale to things. It is so easy to look at photographs of the Space Shuttle and all of its GSE (Ground Support Equipment) and lose sight of just how gigantic everything is, and so, every once in a while, you need to stop, and linger over an image such as this one, and reset your sense of scale, or otherwise your mind will fall right back into a state of blind disbelief and completely fail to comprehend what's really going on here.

Near the bottom left corner of the image, distant across the width of the Flame Trench from the pair of ironworkers in the near foreground, just to the left of MLP Mount Pedestal number 6, wearing a dark blue jacket and white hardhat, Wade Ivey, owner of Ivey Steel, can be seen, never taking his eyes off of things as his people and equipment give yet another demonstration of why they were the best that could be gotten at this sort of thing.

Bottom:

(Full-size with masking)

Under the watchful eyes of just about everybody, the lift proceeds, and the Gox Arm Truss floats ever higher and higher against the crazed backdrop of the FSS and the RSS.

By now, the rotation of the truss was more or less complete, and the hinge boxes are pretty much where they'll need to be when comes time to bolt the truss to the FSS.

Return to 16streets.comACRONYMS LOOK-UP PAGEMaybe try to email me? |